Product presentation is your brand's silent ambassador, visually conveying your values and quality commitment as consumers review their choices on store shelves or receive their shipments from e-commerce sites.

It also serves as a defense tool, safeguarding the contents for its journey through the supply chain. Attaining the perfect container for your items involves several variables, each impacting the overall packaging design cost.

Continue reading as we examine ten common elements influencing the price tag for your physical product's outer protection design.

1. Materials Makeup

2. Size & Shape

3. Printing Methods

4. Graphics Intricacy

5. Branding Assets

6. Compliance Requirements

7. Order Quantity

8. Advanced Features and Add-Ons

9. Eco-Friendly Materials

10. Vendor Choice

Materials Makeup

Do you know the type of package you are using? Carton, pouch, corrugated?

The design process often starts here with pertinent questions about your product's physical characteristics.

Variables such as size, weight, density, fluidity, etc., all influence your choice of raw materials for the packaging. Another factor to consider is whether your items are fragile or relatively sturdy.

Generally, it's a balancing act as you weigh the options of using premium materials to enhance the products' perceived value versus using less expensive alternatives and compromising aesthetics and functionality.

Do you have an adequate budget? If so, perhaps choosing a premium package version will suffice if it aligns with your brand position, target consumers, and the product's physical makeup.

Let's consider an example with a lower price tier.

For a small hand-held item, an entry-level package would be our Poly Bag with a branded topper card, while the most expensive option for the same item would be a Clamshell.

Remember, though, that depending on the item and quantity contained, sometimes the Clamshell is more economical.

To put numbers on the example, for items retailing under $5, the package cost should be under $1, and the initial print run shouldn't be so small that the price per piece is too high, negating profit margins on the product itself.

Consider the pros and cons of each material type, and decide how each one aligns with your budget limitations, item pricing, and brand objectives to balance functionality, visual traits, and cost-effectiveness.

Size and Shape

Your package dimensions influence product presentation, protection, and storability. Numerous unique shapes are available, ranging from standard to complex and custom die-cast structures.

As noted, these come with increased outlay due to specialized manufacturing and limited runs. Using a stock design is certainly more affordable, but remember that they might capture less attention on crowded shelves.

Optimizing for space efficiency greatly impacts packaging costs especially for items selling in large numbers.

Whether this is an existing design or you’re starting from scratch, using a high item-to-package ratio decreases storage expenses while cutting materials waste and environmental impact.

It's okay to prefer a unique or attention-grabbing package style. However, remember to consider other factors such as manufacturing complexity, materials, and shelf space optimization, not to mention those budget limitations.

Printing Methods

Packaging design cost often depends on the chosen graphics style and photo printing required.

Packaging design cost often depends on the chosen graphics style and photo printing required.

Traditional methods include offset and flexography, which should offer ample cost savings for considerable production runs.

Modern techniques include digital and gravure, which offer increased flexibility and shorter lead times.

(Learn more about best package printing methods here)

As with the previous factors, achieving a balance between visual appeal and cost depends on your desired brand perception and the packaging materials chosen.

Less expensive printing methods might result in color and resolution compromises, but this might be acceptable if the product type doesn't warrant an upscale look.

Evaluate the market, the product, and your funding constraints when deciding on how to decorate your packaging, given their raw material makeup.

Graphics Intricacy

Aesthetics and branding appeal often hinge on the complexity involved with your graphic elements, and these traits also affect packaging design costs.

Simple designs allow for considerable savings, though you risk losing consumer attention.

Amping up your graphics with bold colors and intricate patterns or shapes is definitely eye-catching but could be time consuming to create.

Is your brand established?

Do you have assets such as logos and photography or established branded graphics already?

Answering these questions allows you to find the balance between an upscale yet minimalist graphic style and snazzier designs.

It all depends on how much storytelling you'd like to include via written copy or photos and then deciding how to align your brand logos with these complex elements.

Whichever choice you pick, be sure the added costs match up with target consumer expectations and your brand's perceived tier.

Branding Assets

These are the pieces that make your packaging come to life, speaking to consumers through visual motifs like the copy, logos, and colors.

These are the pieces that make your packaging come to life, speaking to consumers through visual motifs like the copy, logos, and colors.

They establish recognition and personality, aligning with your other public-facing assets, such as vehicle wraps or paint schemes, TV, and online presences.

The branding elements' effect on packaging design cost depends on their inclusion methods and complexity.

Using special textures, customized logos and materials, and unique color schemes within the limited space allotment could entail additional formatting work, intricate printing processes, and increased capital outlay.

Templates or minimal branding additions may be cost-effective but perhaps inappropriate for luxury products. Personalization tailored to specific audiences might include increased production expenses.

Balance your budget limitations and brand strategies with visual customization choices to create containers that provide adequate product protection while achieving your desired consumer messaging agenda and government labeling compliance.

Compliance Requirements

Regulatory standards exist to enforce product safety and integrity for consumers.

Satisfying these standards often requires significant collaborative efforts, which impact your overall packaging design costs.

Depending on the nature of your product, you'll need to include certain labeling information within the customer facing areas of the container.

Food items require nutrition information, sell-by dates, and cooking instructions.

Some products require packaging with specific attributes like moisture protection, padding, crush-proofing, child safety protection, and see-through windows.

Researching and designing these modifications often comes with a significant capital expense, and compliance failure may lead to legal exposure and threaten consumer trust and loyalty.

Order Quantity

Chances are you learned about economies of scale in many college courses, and it comes into play when discussing packaging design costs.

When you order customized product containers like jars, bottles, pouches, and boxes, fabricators like to spread their fixed expenses over larger production cycles.

Tooling, programming, and machinery setups must be done in advance, so running these parameters to produce more customized containers results in lower per-piece costs.

Note that while smaller batches often mean high per-unit costs because of the setup required, they also give you more flexibility to make design changes or respond to changes in market demands—perhaps adding larger adhesive flaps on boxes or refreshing the existing graphics on polymer pouches.

Consider the scaling trade-offs when deciding your optimal packaging order volumes.

Advanced Features and Add-Ons

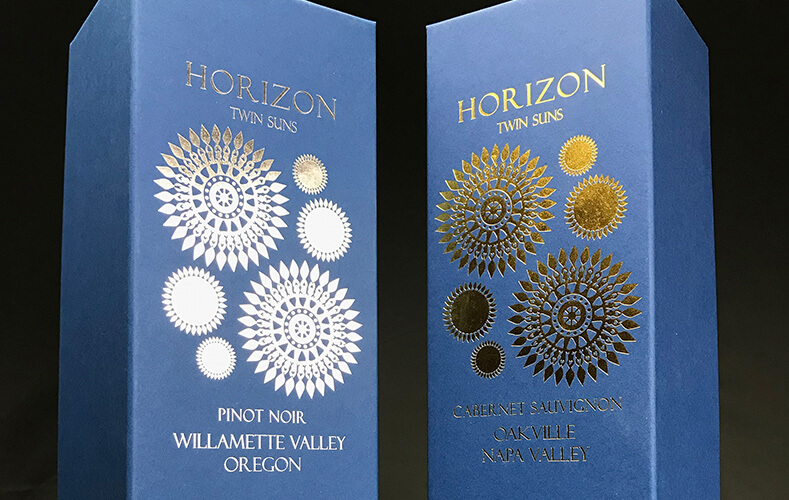

Ordering extras like embossment, foil stamping or UV coating might add that sophistication you desire to impress consumers, but they often require specialized skills and machinery to produce.

These premium materials and additional manufacturing processes mean increased costs on your behalf. Consider the value proposition for these add-ons to your branding and packaging objectives.

These premium materials and additional manufacturing processes mean increased costs on your behalf. Consider the value proposition for these add-ons to your branding and packaging objectives.

Some special features may provide improved functionality to customers. Convenient handles for lifting and compartments for small accessories will enhance the user's experience, but also boost your overhead.

Consider the pros and cons of increased usability, aesthetics, and the added expenses before making large-quantity orders to avoid surprises from your packaging design costs.

Eco-Friendly Materials

Sustainability has emerged as an important consideration for packaging manufacturers. Consumers are increasingly conscious of eco-threats and prefer using materials that align with conservation efforts.

Including options like compostables, recyclable substrates, and biodegradables reduces waste and lets customers take an active role in preserving our environment. These efforts may include a higher investment penalty compared to conventional materials.

Vendor Choice

Not all custom product packaging design & manufacturing firms are equal. Choosing the right provider and establishing a long-term partnership is paramount to reducing your packaging design cost without compromising quality and safety.

At Catalpha, we’ve helped many consumer product goods companies just like yours increase their sales between 10% and 100% with our industry-leading custom packaging solutions and point-of-purchase (POP) displays.

Our mission is to provide you with superior brand packaging design so you can sell more products.

We do it all for you - From Concept to Design to Printing

Catalpha has a proven collaborative design process for creating product packaging that sells. We’ll define your product’s USP (Unique Selling Proposition) and deliver a stunning graphic design that’s truly you.

We are the leader in Luxury Packaging, Short Run Retail Box Printing, and Custom Corrugate Display Solutions for industries such as food & beverage, health & beauty, and pet care products.

We’ll integrate your new branding and apply it to any popular box styles, including:

- 5-Panel Hanger

- Box Sleeve

- Auto Bottom

- Tuck Flap

- Stand Up Pouch

- Carton

- Corrugate Boxes

If you’d like your own specific box style and fresh artwork, our designers will collaborate with you to create a stunning and attractive package to fit your product and maximize its retail shelf and trade show appeal.

For stunning Custom Product Packaging and Point-of-Purchase Displays, contact Catalpha today.