The finish can be enhanced with the addition of specialty coatings to create a super high gloss, matte or soft-touch finish to increase the perceived value of your products.

Compared with other printing methods, there is virtually no banding, creating a smooth color gradient in the printed graphics.

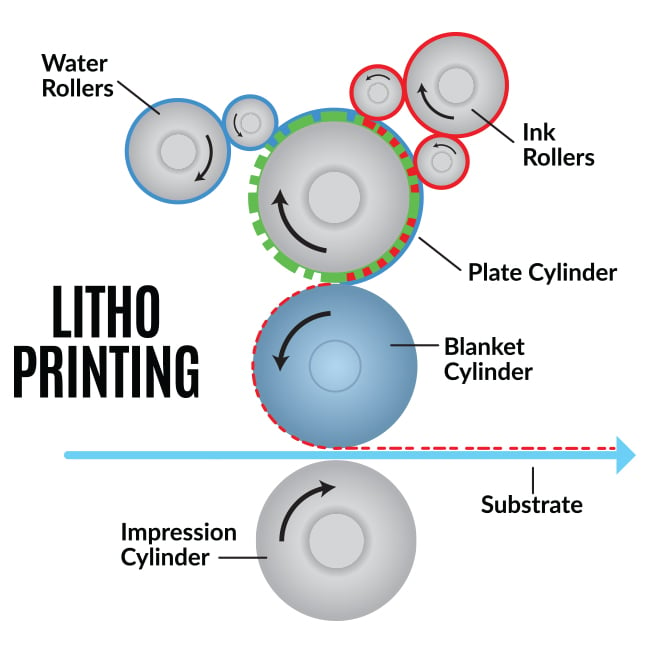

The Downside To Lithography Printing

It requires a significant investment in tooling to create custom printing plates. But those are a 'one-time' charge and assuming there are no changes to artwork when you need to print more packages, you will be able to re-use your print tooling for that run.

Lead times are also longer. And to keep lithography printing for packaging cost-effective, high volumes are typically better.

|

|

| Here's a detail showing magnification of lithographic printing. Note the regularity of the print. Offset printing creates a regular pattern. |

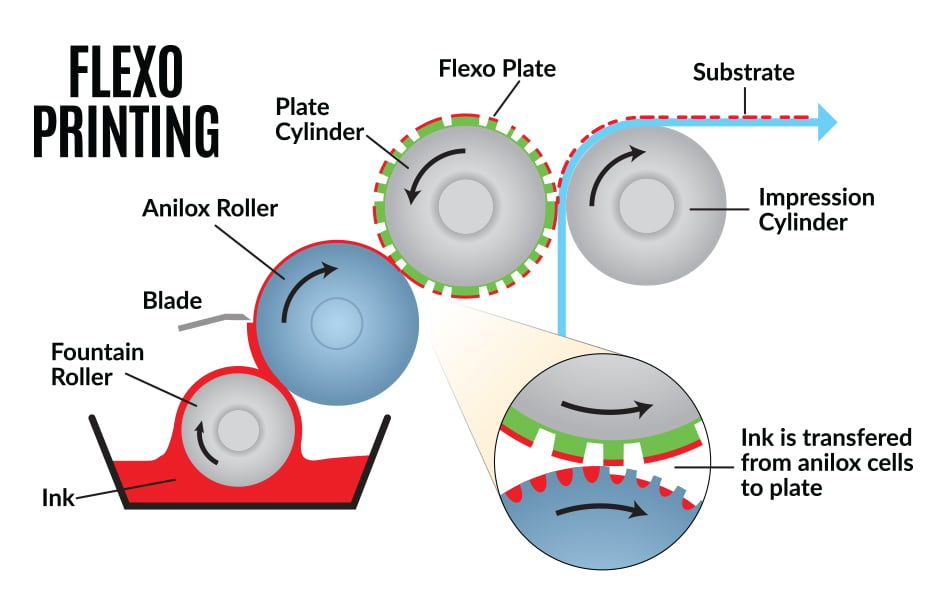

2. Flexographic Printing

Best Used For: Very High Quantities

Printing for flexible packaging is becoming increasingly popular due to the numerous benefits this packaging type offers.

Flexographic printing for packaging, also known as flexo printing, is commonly used for flexible packaging such as stand up pouches.

It can also be an effective printing for packaging solution for corrugated boxes.

One of the advantages of flexographic printing is that it is cost-effective per unit.

One of the advantages of flexographic printing is that it is cost-effective per unit. As the tooling costs are lower, this saving can be passed onto you.

Turnaround times are typically much faster than with other printing for packaging methods.

And, with flexo printing, you can use both water-based and oil-based inks, giving you more options.

The Downside Of Flexo Printing

On the other hand, compared with lithography printing, the quality can be noticeably less.

Banding can occur, as the color gradients are not always smooth and it has a hard time reproducing photo-quality images to a high standard.

However, despite these downsides, flexographic printing’s affordability helps it to maintain its popularity when it comes to printing for packaging.

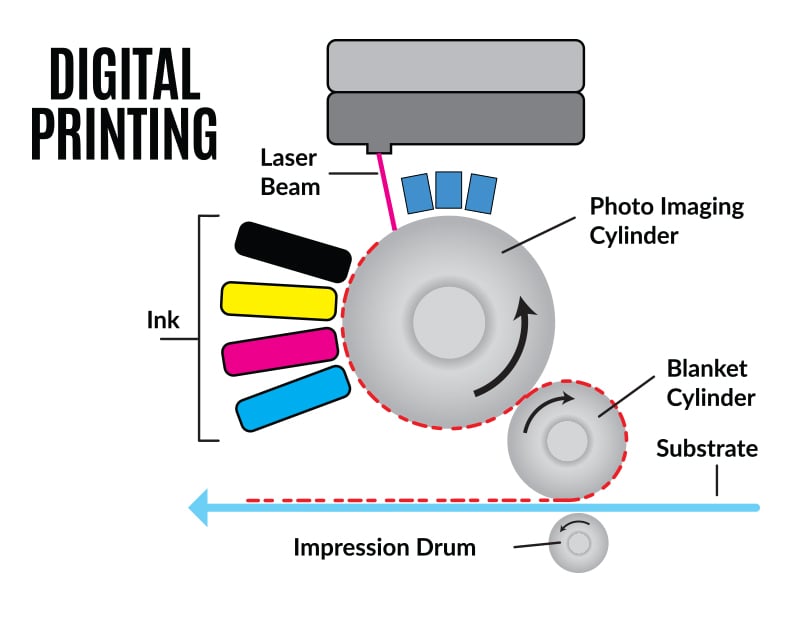

3. Digital Printing

Best Used For: Low Quantities, Fast Turnaround

As one of the most versatile printing methods for packaging solutions, digital printing has countless applications.

Digital printing is highly effective in producing top-class print quality for labels, corrugated boxes, folding cartons, prototypes, stand up pouches and more.

In addition to its versatility, digital printing also offers fast turnaround times, sometimes within 2 weeks, and there are very little tooling or set-up costs associated with this printing for packaging method.

In fact, there are usually no die plate charges as all die cutting is usually done via an automated cutting table.

Low minimums are typical and the print quality is almost as good as lithographic printing, creating amazing final results.

Advances in corrugate digital printing has made this method a go to source for companies getting started or testing new products OR new packaging.

Digital printing is highly effective in producing top-class print quality

The Downside Of Digital Printing: Not Cost Effective For Large Quantities, No Custom PMS Spot Colors Available.

However, there are a few negatives to digital printing for packaging.

If you are printing in large volume, the costs can add up quickly. So there is a quantity point where another package printing method may be more economical.

Pantone Matching System (PMS) colors can also be challenging to match and there are not as many coating options as are available as with lithography printing for packaging.

Although the price per unit can be high, digital printing can be an excellent solution depending on your needs.

|

| Detail of digital ink jet printing on corrugate. Note the pattern of ink. Inkjet printing created a dispersed pattern of ink. A digital laser print will more closely resemble offset lithography. |

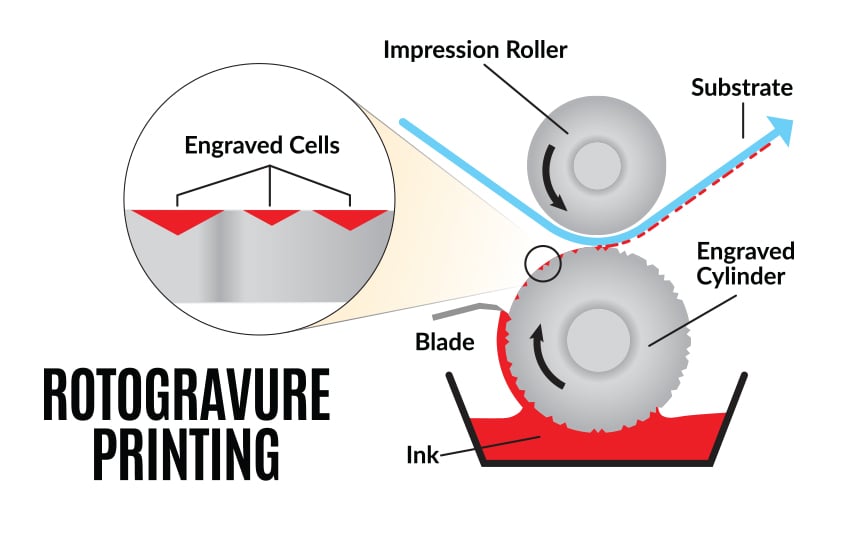

4. Rotogravure Printing

Best Used For: Very High Quantities, Precision Color

Most commonly used in flexible stand-up pouch printing and on folding cartons, rotogravure printing for packaging is one of the most widely used printing techniques for high volume printing.

Also, known as gravure printing, this method is often used in printing packaging designs.

rotogravure printing is still one of the most popular printing options and could be the perfect printing for packaging solution for your business

Rotogravure printing offers excellent print quality and is more than capable of reproducing high-quality photo images.

Printing times are very quick, with modern presses capable of producing fourteen meters of film in a single second!

Rotogravure printing can produce continuous-tone images, meaning consistent high-quality prints, even at high volume.

The Downside: High Initial Cost, Fewer Coating Options

Although gravure cylinders are very durable and can be used for multiple printing runs, the original cost is very high.

There are not a lot of coating options available and for it to be cost-effective, higher volumes are generally required.

However, rotogravure printing is still one of the most popular printing options and could be the perfect printing for packaging solution for your business, especially if you require high-volume, top-quality printing for your packaging.

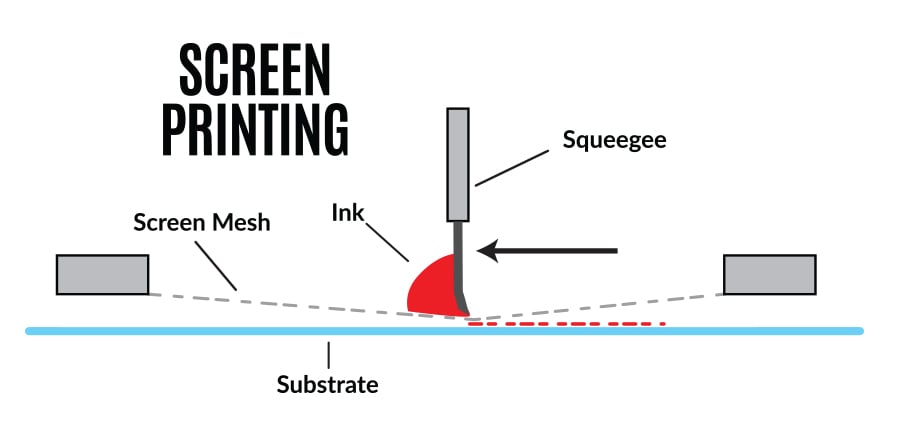

5. Silkscreen Printing

Best Used For: Low Quantities, Fewer Colors

Silkscreen printing produces a clean, sharp finish with printed images and text.

This printing for packaging method can be used on a wide range of materials, such as fabric, corrugated packaging, and plastics.

| Samples of screen printed bottles and jars. Screen printing is used to print on rounded or irregular shapes of containers. Image courtesy of bluelinelabels.com |

It can be used for prototypes, labels, promotional materials, corrugated boxes, and folding cartons.

Silkscreen printing is an excellent choice for businesses that use pre-made or stock packaging.

This printing for packaging method is an excellent choice for businesses that use pre-made or stock packaging.

It is also the perfect choice for printing marketing and promotional materials such as t-shirts and mugs.

| Samples of screen printed corrugate boxes. Image www.onepoundcoffee.com |

Set-up costs are typically very affordable and it’s a good solution for smaller volume jobs. Silkscreen printing is best used on corrugate packages and surfaces that are not flat.

The Downside: Slower Turnaround, Not Photo Quality

Some disadvantages of silkscreen printing for packaging are that turnaround times can be slower than litho printing and it is more susceptible to human error.

The finish is not usually as clean and it is difficult to reproduce photo-quality images with any real conviction. With that said, silkscreen can be the perfect solution for smaller volume packaging jobs and prototypes.

Use This Chart To Help You Choose The Best Package Printing Method To Suit Your Needs

| Printing | Less than 100 pieces | Less than 1000 pieces | More than 1000 Pieces | Quick Turnaround | High resolution printing | Small budget | Custom ink spot colors |

| Litho | • | • | • | • | |||

| Flexo | • | • | |||||

| Digital | • | • | • | • | |||

| Rotogravure | • | • | • | ||||

| Silk Screen | • | • | • |

When it comes to printing for packaging there is no one-size-fits-all solution.

With so many variables at play, it’s always best to get the advice of an experienced and reputable packaging design company to ensure you make the right decision.

Here at Catalpha, our team has the knowledge and expertise to help you take the best possible approach to your packaging design to ensure the best outcome possible. Get in touch today to see how we can help you with your printing for packaging needs.

Need more help with your packaging? Here are a few other blog posts that might help explain the packaging process:

How Much Will My Packaging Cost?

Custom Packaging For Small Business – Why It’s Important & How To Get The Best Results

Follow This 10 Step Process To Create Packaging Design That Sells Your Product

Do you have more questions on package printing that we didn't cover? Let us know on the form below...